IMPA: 67 38 11 - 67 38 21

With 30 years of experience as a GRP manufacturer - Made in Italy

With 30 years of experience and the exclusive manufacturing process system Teknotex, Eurograte® has a leading position in the European market.

Eurograte®, differently form all other FRP moulded gratings, distinguishes itself for:

Teknotex manufacturing process, unique worldwide, which assures a product with constant quality and mechanical properties

use of best quality raw materials, made in EU, which means more safety and absence of forbidden (toxic) components

eco-friendly manufacturing process

best working environment for employees

Functionality and safety

LIGHT WEIGHT

A well-known feature of fiberglass is the high strength-to-weight ratio. EUROGRATE® FRP gratings weigh less than 1/3 of comparable steel gratings!

That means reducing weight on the structure, saving money and increasing safety during installation.

Furthermore, the light weight enables an easy handling and cleaning of the gratings.

FIRE RETARDANT

EUROGRATE® with its special resin systems, satisfies most of the safety issues and regulations for applications where it's necessary to limit the spreading of

flames and smoke.

ELECTRICAL INSULATION

EUROGRATE® FRP gratings, thanks to the intrinsic feature of fiberglass, provide electrical insulation. This feature makes expensive "grounding" not needed and increases safety on the job site. The installation is thus quicker and cheaper.

MAINTENANCE FREE

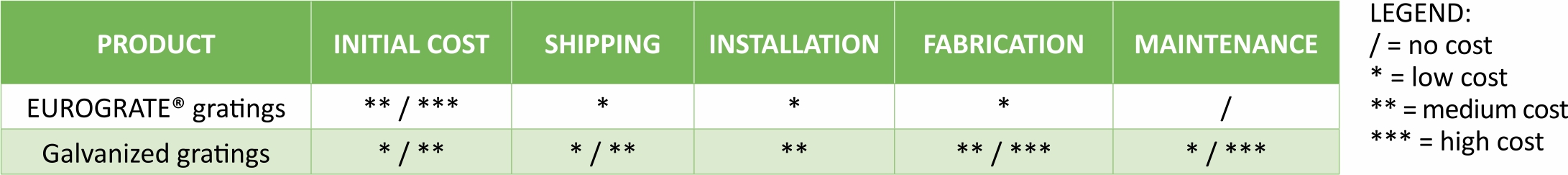

Metal gratings have a lower initial cost than FRP gratings, but considering the life cycle costs this is not the most economical choice, because of the high maintenance and replacements costs that occur once steel is corroded.

EUROGRATE® FRP gratings have an incredibly long service life, they do not need scraping, sandblasting or coating even after many years of service, becoming

more economical compared to traditional metal gratings.

CORROSION RESISTANCE

EUROGRATE® FRP gratings are manufactured with polyester resins reinforced with fibreglass strands, selected for their corrosion and mechanical resistance, are ideal for almost all industries which face corrosion problems on a daily basis.

The premium grade resins used (such as polyester, isophtalic, vinyl ester and phenolic, depending on the specific application) are the right trouble free solution

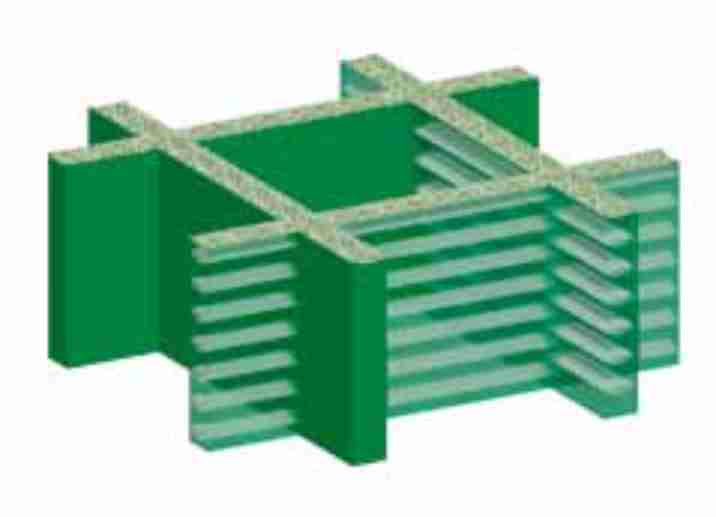

EUROGRATE® GRATINGS ARE MANUFACTURED WITH AN EXCLUSIVE TEKNOTEX PROCESS

MECHANICAL RESISTANCE

The continuous interwoven fiberglass strands give EUROGRATE® FRP gratings a remarkable mechanical resistance, comparable to metal grating ones.

The monolithic construction and the mesh of glass fibers provide an optimal load distribution in both directions. If the grating is accidentally overloaded, no permanent deflections occur.

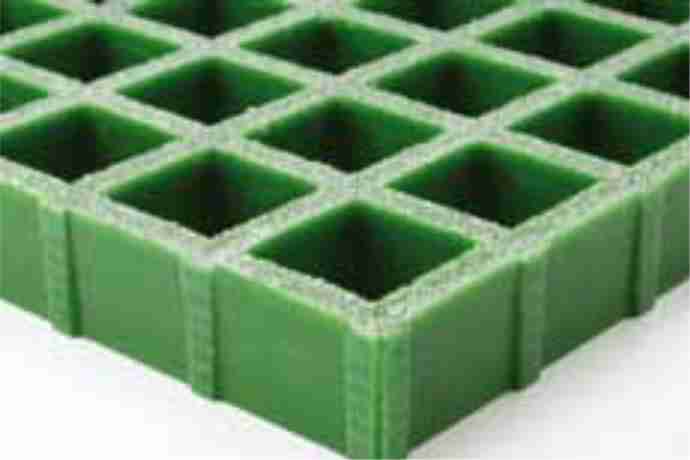

PERMANENT SLIP RESISTANCE

EUROGRATE® FRP gratings are manufactured with a special anti-slip surface using integrated quartz grains to decrease the risk of slips and falls.

The integration of the quartz grains in the surface of the EUROGRATE® panel, assures a long lasting durability and a superior adherence compared to any other type of grating even in presence of water, ice, oil or grease.

The EUROGRATE® anti-slip surface is classified R13-V10 according to the DIN 51130 norm positioning the surface as the highest possible anti-slip solution.

Other types of surfaces are available on demand.

SAFE AND COMFORTABLE FOOTHOLD

The mesh dimensions provide a comfortable foothold (ergonomics), promoting a safe and comfortable walk.

The resiliency decreases typical backache due to long standing time.

INSTALLATION AND MAINTENANCE: EXTREMELY EASY

EUROGRATE® FRP gratings are manufactured in standard panel sizes (see data sheets), customized sizes can be supplied on request.

Light weight, easy handling and the possibility to cut the material directly on the site, makes the installation easy and decreases considerably installation costs.

Since EUROGRATE® gratings don't contain metal parts, they can be easily cut without edge banding and no special protections on the cut edges is required.

Thanks to their peculiar properties, EUROGRATE® gratings are maintenance free.

RADIO TRANSMITTANCE

Thanks to its structural composition, EUROGRATE® FRP gratings are suitable for applications where it is necessary to avoid any interference with radio waves (i.e. airports, RF testing facilities, MRI rooms, etc.).

Surfaces: Safety as a priority

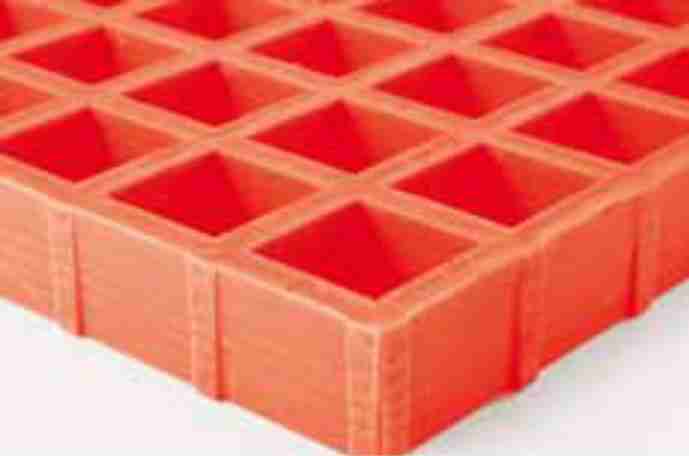

ANTI-SKID SURFACE

This is the best solution to work in total safety even in worst conditions (presence of water, ice, oil, wax, grease, etc.).

The particular integration of the silica grains assures an excellent wear resistance and a long-lasting durability of the surface.

Classified: R13-V10 according to the DIN 51130 norm.

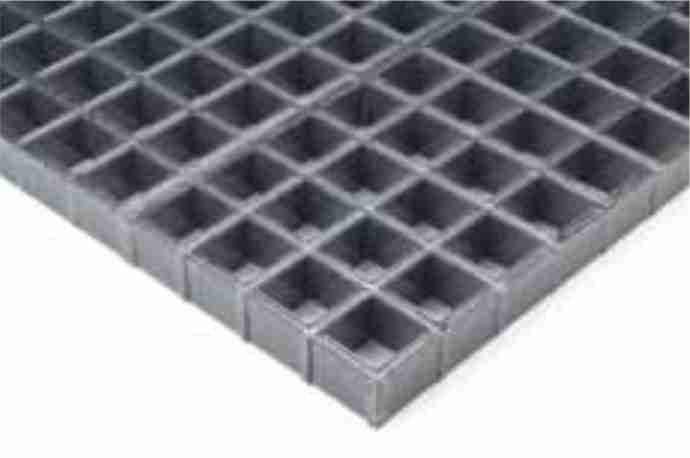

CONCAVE (MENISCUS) SURFACE

An alternative to the traditional anti-skid surface proposed with a competitive price.

Suitable for applications where the use is not as frequent but safety is the same a fundamental requirement.

Classified: R13-V10 according to the DIN 51130 norm.

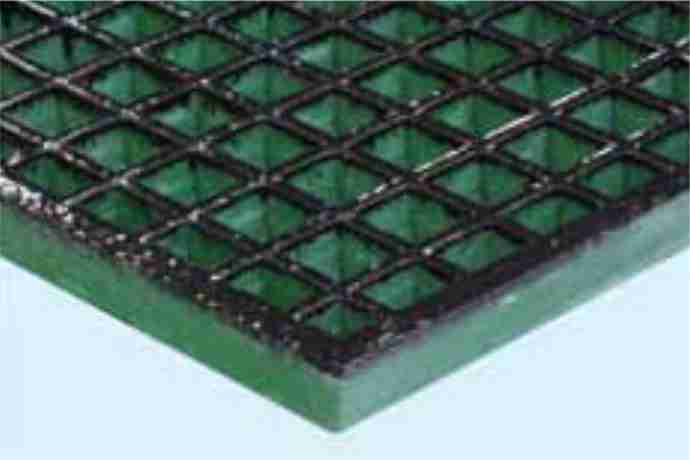

CLOSED SURFACE

This surface allows the separation between two levels: it prevents drippings or smoke to pass and assures complete safety for below pedestrian transit. The right solution for applications where forklift and trolley transit is frequent.

Classified: R13-V10 according to the DIN 51130 norm.

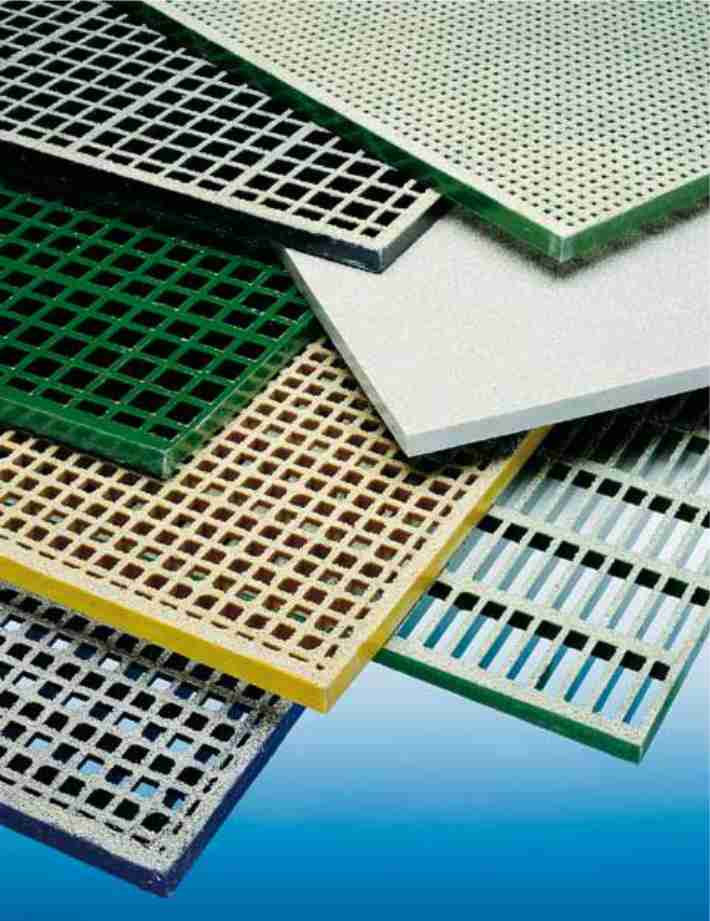

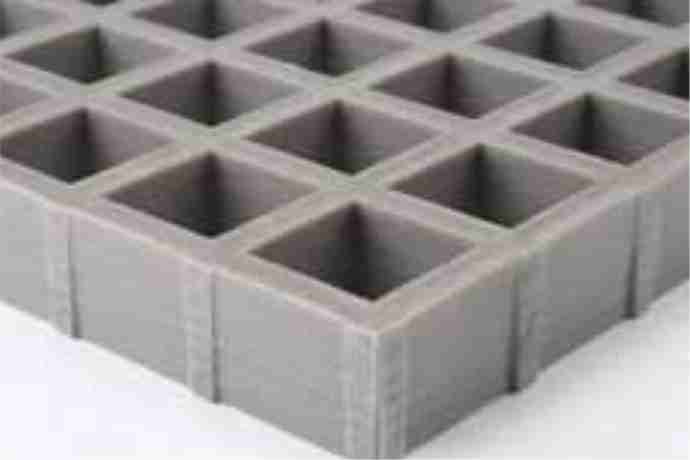

CUSTOM RESINS & COLOURS

Customized grating colours and special resin systems can be formulated as an option to the customer's requirements.

FULLY CONDUCTIVE RESIN

Properly grounded, this special conductive version is suitable for frequent use and does not allow the build-up of unwanted static electricity maintaining all the other features of traditional FRP gratings.

Suitable for ATEX zones.

CONDUCTIVE SURFACE

Properly grounded, this special conductive version is suitable for occasional use and does not allow the build-up of unwanted static electricity maintaining all the other features of traditional FRP gratings.

Suitable for ATEX zones.

CHECKER PLATE SURFACE

Suitable for occasional use, this surface is made by moulding the resin creating an anti-skid surface without using silica grains replicating traditional metal checker plates.

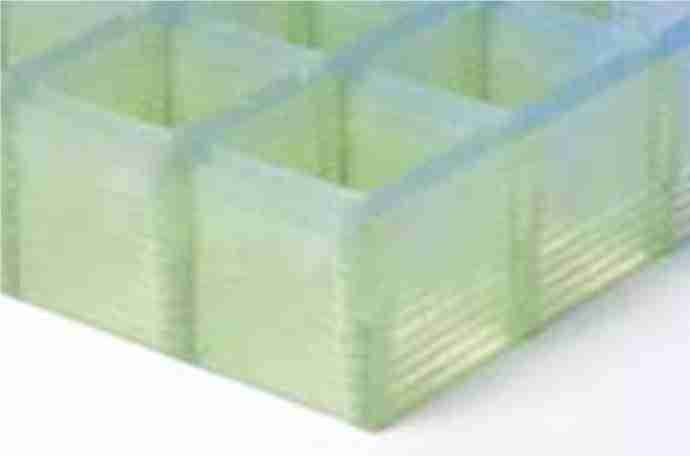

TRANSLUCENT RESIN

This solution is designed for architectural and residential applications. Made with special raw materials (fire retardant also available), this version can be supplied on demand in several translucent colours.

PEEL-PLY SURFACE

This peculiar surface is an alternative to the traditional anti-skid version, without the use of silica grains. It is available on closed gratings and flat panels.

Safe Stairways

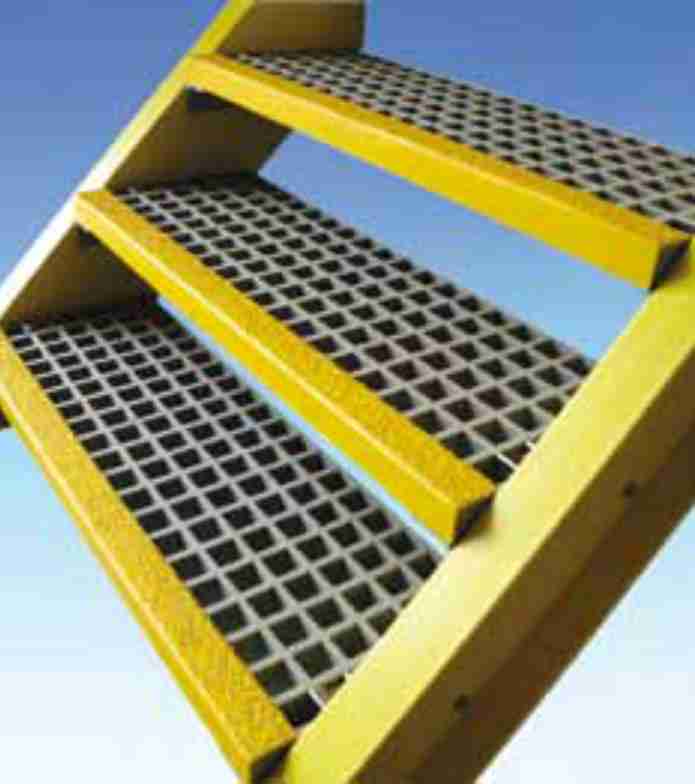

EUROTRED® STAIR TREAD

This product is the result of an in-depth study of accidents occurring on stair treads and around stairways. Manufactured with the same criteria as EUROGRATE® gratings, with a reinforced nosing of a different colour and with a permanently integrated anti-slip surface, EUROTRED® is a maximum safety product. Its installation is highly advisable for any potentially hazardous area.

Safety is enhanced also thanks to the tread's mesh pattern which complies to the French norm 62-1028 (dated 12th August 1962) which requires that objects with Ø 20 mm should not pass through the mesh (T4 & T6).

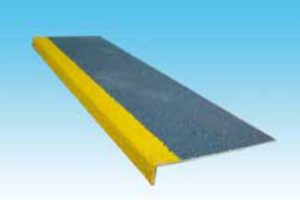

EUROSTEP® AND SECURSTEP® STAIR COVER

EUROSTEP® (moulded) and SECURSTEP® (pultruded) stair covers are the right solution to make stairways safer, both in civil and industrial applications. They can be installed on all existing steps (made of wood, concrete, steel, etc.) with mechanical or chemical fixing. The special permanent integration of silica grains gives an excellent slip resistance in all extreme conditions (presence of water, ice, grease, oil, wax, etc.).

EUROSTEP® (moulded) and SECURSTEP® (pultruded) stair covers are the right solution to make stairways safer, both in civil and industrial applications. They can be installed on all existing steps (made of wood, concrete, steel, etc.) with mechanical or chemical fixing. The special permanent integration of silica grains gives an excellent slip resistance in all extreme conditions (presence of water, ice, grease, oil, wax, etc.).

EUROSTEP® and SECURSTEP® stair covers are supplied with a safety yellow front nosing to make the step immediately visible, thus increasing worker awareness and consequently reducing possible accidents.

EURO SAFETY STEP

The new EURO SAFETY STEP is a stair safety edge with size 70x40 mm and represents an economical solution to solve slip problems on existing stairways.

The main features are: chamfered edge, integrated and permanent anti-skid surface, with a yellow-safety colour.

EURO SAFETY STEPS can be easily fixed with glue or anchor bolts to the existing stairs

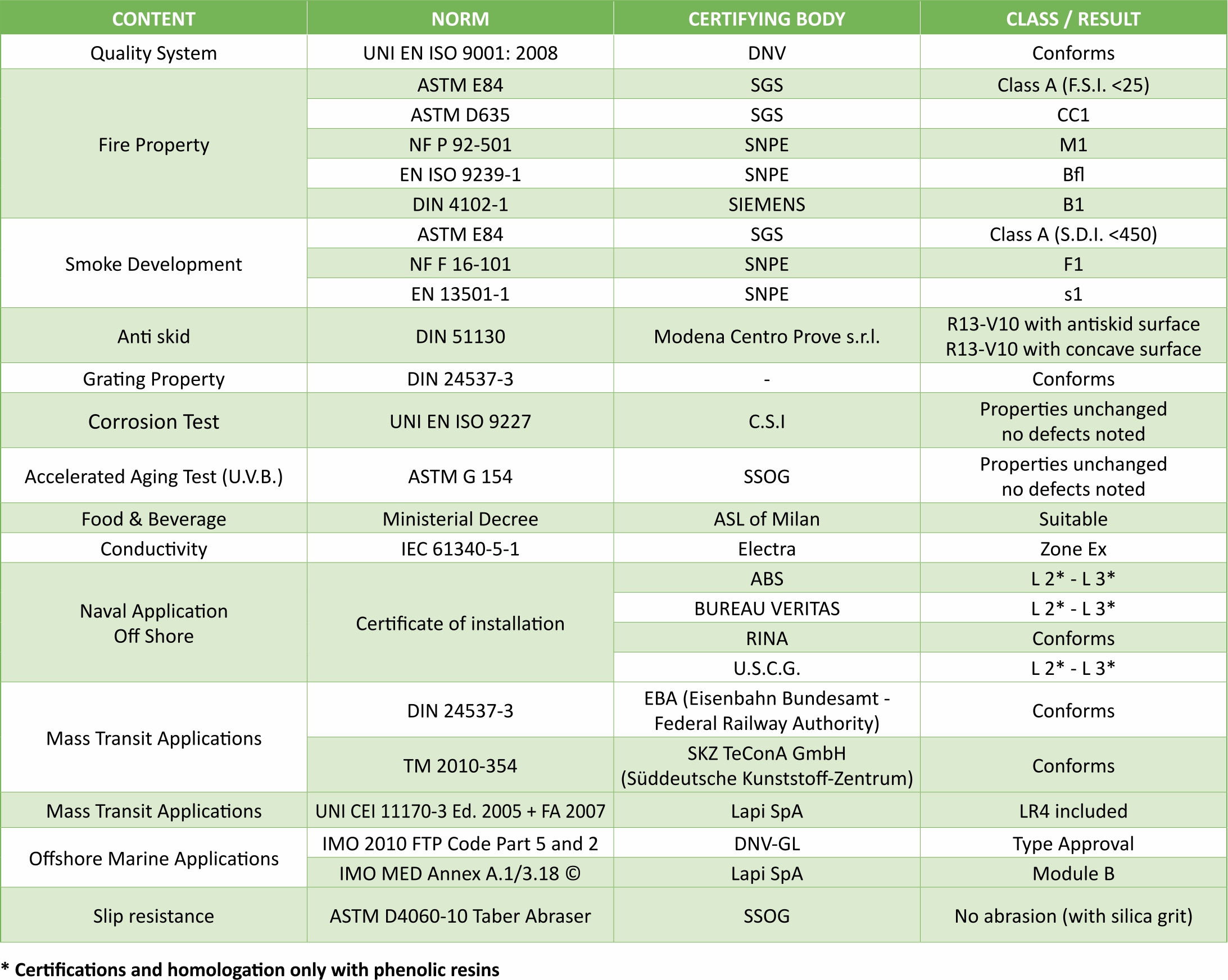

Approvals

Accessoiries

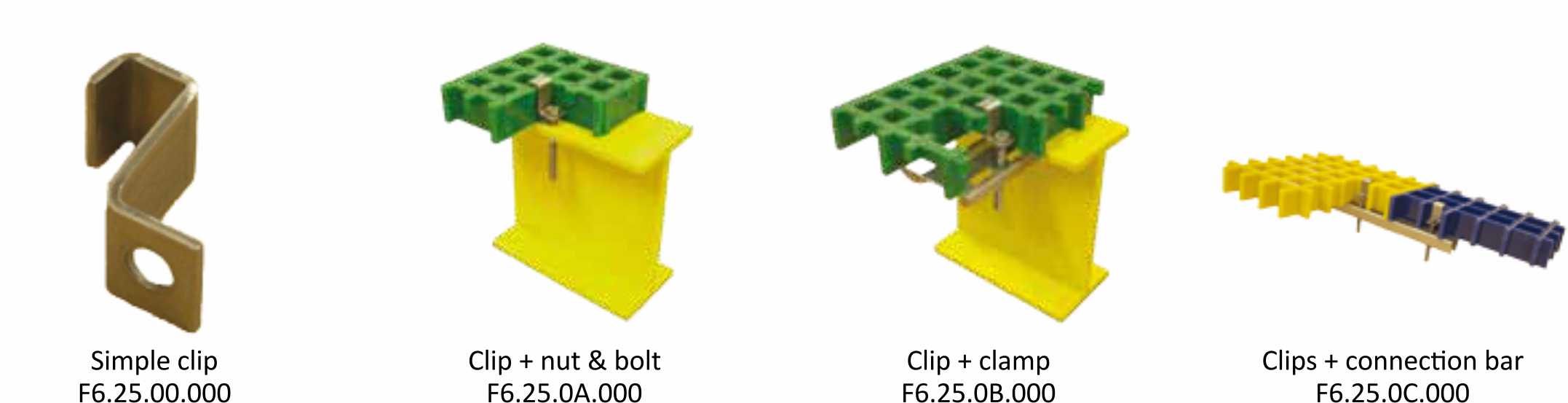

GRATING FASTENERS - "J clip" TYPE

"J clips" are used to fix open mesh gratings with different thicknesses (13, 20, 25, 30, 38 mm). These clips can work together with nut & bolt (A), with fixing clamp (B) and with connection bar (C). All components are made of Aisi 316 stainless steel (zinc plated on request).

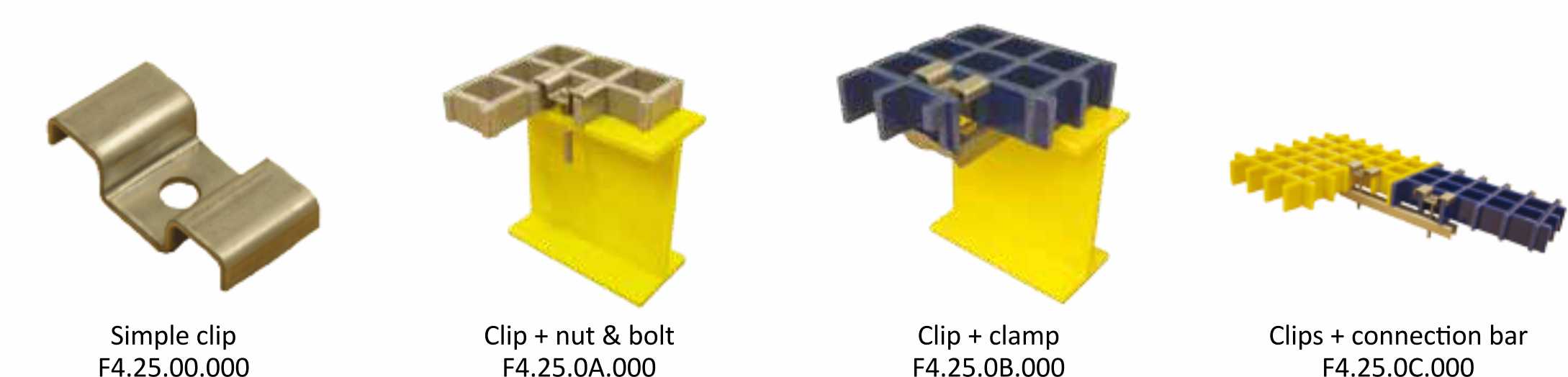

GRATING FASTENERS - "M clip" TYPE

"M clips" are used to fix square mesh 30x30 mm with different thicknesses (13, 20, 25, 30, 38 mm). These clips can work together with nut & bolt (A), with fixing clamp (B) and with connection bar (C). All components are made of Aisi 316 stainless steel (zinc plated on request).

GRATING FASTENERS - "Disc" TYPE

Grating fasteners "disc" type F7.25 are used to fix closed and flat panels, and stair covers. Grating fasteners "disc" type F0.25 are used to fix square mini-meshes 8x8, 13x13 mm with different thicknesses (22, 30, 40 mm) or rectangular mesh 50x25 h 55 mm. These clips can work together with nut & bolt (A), with fixing clamp (B) and with connection bar (C). All components are made of Aisi 316 stainless steel.

Fabrication and installation

CUTTING

Cutting EUROGRATE® FRP gratings is quite easy and similar to working with wood, keeping in mind some simple notes.

We suggest using a circular power saw with a masonry diamond tipped blade to obtain a perfect, high quality straight cut. A standard rotation speed without excessive pressure is usually suggested.

In case of circular cuts, we suggest using a jig saw with a diamond tipped blade to obtain a high quality cut. For limited cuts it is possible to use a standard jig blade; in this case, obviously, the quality of the cuts will slightly decrease. If the blade should clog with fiberglass, we suggest cutting a solid masonry brick to clean it.

Tools must be often cleaned because fiberglass is very abrasive.

FINISHING

EUROGRATE® FRP gratings are resistant to environmental and chemical corrosion, therefore they don't require sandblasting, painting or coating even after many years of service. If gratings are installed in highly corrosive environments, we suggest to seal cut areas with a protective resin to restore the original chemical resistance and to protect the glass fibers that were exposed after cutting, this prevents possible corrosion attacks or introduction of corrosive agents.

On request, a resin sealing kit is available. All the necessary components and accessories are supplied in order to simplify this procedure together with the instructions.

EDGE-BANDING

After EUROGRATE® FRP gratings have been cut, traditional edge banding on the open sides (as metal gratings) is not required because the mesh bars are loadbearing and therefore don't suffer from local buckling.

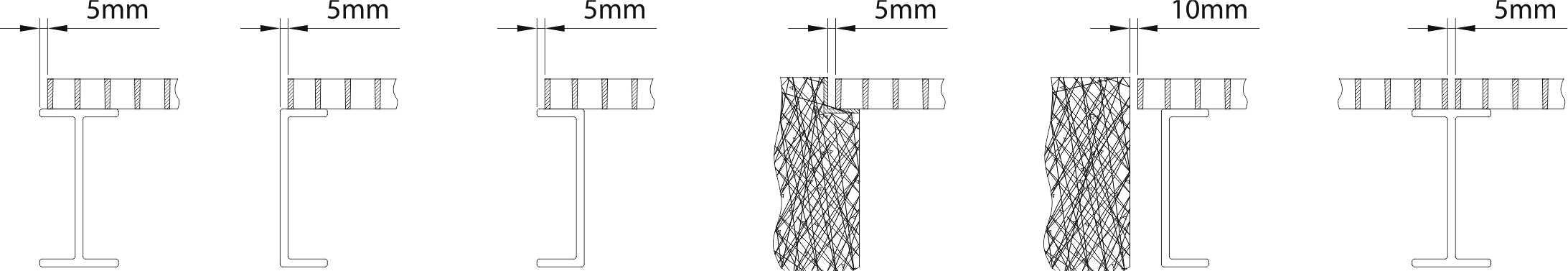

INSTALLATION

When installing EUROGRATE® FRP gratings, please consider a free distance of 5-10 mm along all sides (depending on the installation, temperature, application and product).

EUROGRATE® FRP gratings must be fixed with special fasteners (minimum 4 fasteners per panel). Closed panels have a natural tendency to warp, therefore we strongly suggest to fix them to the below structure with appropriate fasteners.

Material of fasteners must be evaluated depending on the environmental conditions (zinc plated or AISI 316 stainless steel).

The width of the supports must be at least equal to the height of the grating panel in order to distribute correctly the load and stresses. If for example the grating used is a mesh 19x19 H30, then it would have to be supported by at least a 30 mm width beam on each side.

Maybe you didn't know...

Why choose an EUROGRATE® FRP grating?

Have you ever calculated installation and maintenance costs related to metal gratings?

How much are you willing to risk in terms of safety?

LOOK OUT!

Metal gratings are not always the best solution, even though the initial cost may be lower than FRP gratings.

Why be satisfied when you can get a better product in terms of cost/benefit?

Don't underestimate composites! Maybe you don't know that EUROGRATE® FRP gratings ...

1. have a mechanical resistance similar to metal;

2. are almost eternal, are corrosion resistant and assure an unlimited service life;

3. are virtually maintenance free;

4. assure total worker safety even in extreme conditions (grease, oil, wax) thanks to the excellent anti-skid surface inalterable over all the gratings' service life (R13-V10 class according to 51130 DIN norm);

5. are lightweight (with the resistance being equal, the weight is 50% less than steel): their lightweight brings ease of handling and installation therefore saving a lot of money in additional costs;

6. are non-magnetic and not conductive = they don't need expensive grounding (cost saving);

7. are fire retardant, furthermore our "halogen free" formulations assure a low toxic smoke emission in case of fire and do not contain any banned additives.

EUROGRATE® be sure to spend your money wisely!

A strategic quality choice

Structural concept:

Product made in the EU (Italy), the grating must be manufactured in a single moulding process (monolithic product) using continuous pre-tensioned and preimpregnated glass fiber roving strands, thoroughly wetted with a chemical resistant polyester, orthophthalic, isophthalic or vinyl ester halogen-free fire retardant resin system. All the phases of the production process must be managed by a PLC system which assures electronic control during the moulding phase, keeping the right mixing ratio of the resin and a constant tension in the glass fibers, avoiding any type of error that could be made during a manual process (worker).

The mechanical weaving process must assure an even distribution of the glass fibers within the mould and allow the resin to penetrate within the glass fiber strands assuring a complete wet-out of the fibers. Other weaving technologies, such as manual moulding or RTM systems (injection) are not accepted as they are not able to assure a complete wet-out of the glass fiber strands when using fire retardant "halogen free" resin systems which are typically quite dense and viscous and therefore difficult to process.

Anti-skid surface:

EUROGRATE® FRP gratings must have an anti-skid surface achieved through the combination of a permanent integration of silica grains, with a double protective coating made of UV resistant vinyl ester resin to increase the surface chemical resistance, and the concave surface of the bearing bars to increase wear resistance. Silica grains have a granulometry between 0,4 and 0,8 mm and must not be present on the vertical walls of the mesh. Simple concave surface and/or spraying silica or corundum grains are not accepted for their weak wear resistance.

The grating surface must be approved according to DIN 51130 norm and classified R13-V10.

Fire retardant:

EUROGRATE® FRP gratings are fire retardant classified Bfl-s1 according to EN 13501-1 European Norm, M1-M2 according to AFNOR NF P 92-501 norm, class 1 (F.S.I. <25) according to ASTM E-84 norm and 100 according to ENEL DS 4974 norm.

EUROGRATE® FRP gratings have low emission and low smoke toxicity (halogen-free) classified F1 according to NF F 16-101 and class 1 (S.D.I. <450) according to ASTM E-84 norm.

Behaviour to environmental atmosphere:

Products, tested according to ASTM G154 norm, must not show significant changes in mechanical resistance after a 1000 hours accelerated aging, UVB irradiation and water condensation/evaporation cycles.

Local experts and help around the clock

Eurograte® is a registered mark and manufactured by:

ticomm & PROMACO s.r.l.

20064 Gorgonzola (MI) - ITALY

Via Parini, 111/e

Tel. +39 02 95091.1

Fax +39 02 9514897

Deutsche Niederlassung: EUROGRATE GmbH

Berliner Ring 89, D - 64625 Bensheim

Tel. +49 (0) 6251/ 82651-0, Fax +49 (0) 6251/8265199

info@eurograte.de

www.eurograte.de

English

English Deutsch

Deutsch