IMPA: 85 01 91 - 85 12 00

Safety and efficiency on board - Non-corrosive solutions for the marine industry

Always a perfect fit for the marine industry

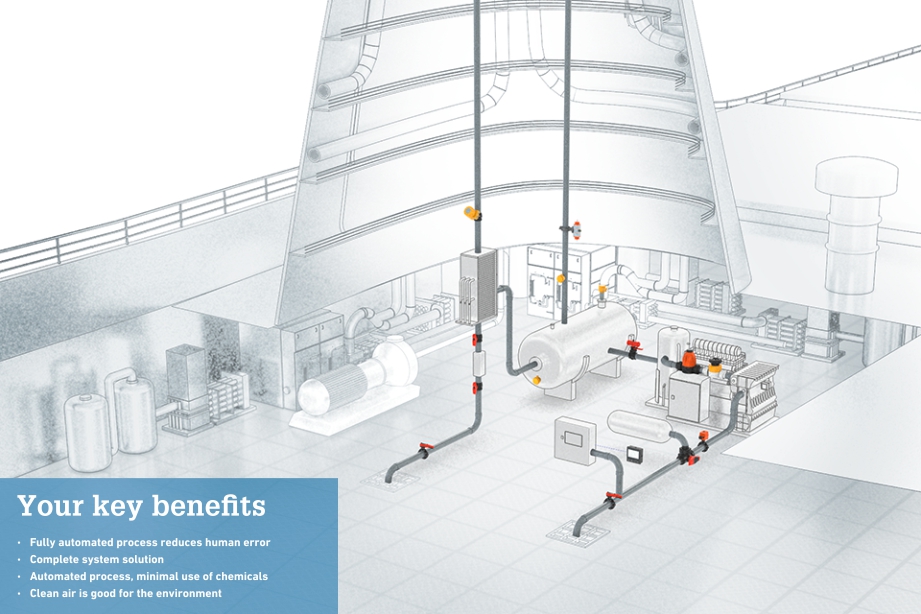

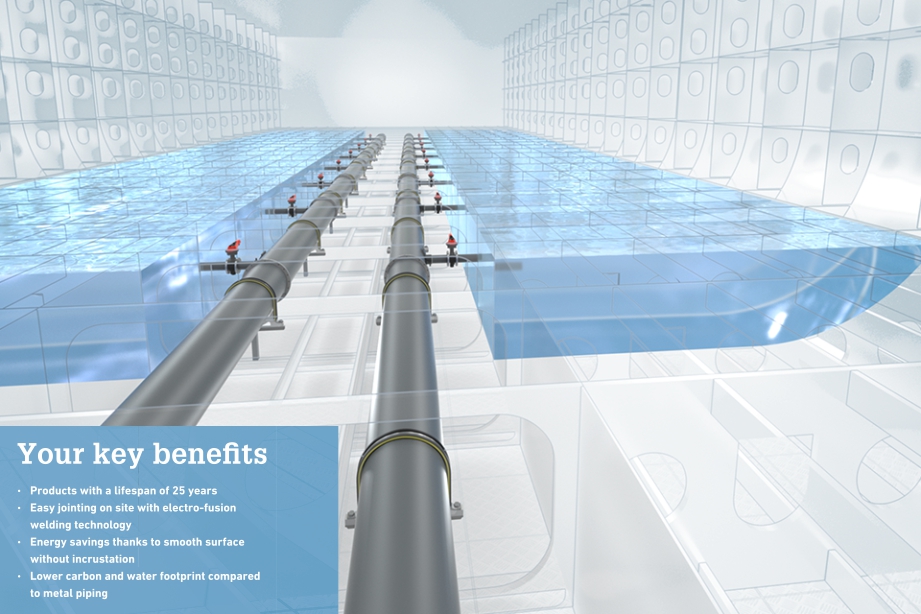

The maintenance-free, easy complete solutions of GF Piping Systems for water and cooling applications on board help you to increase the safety and comfort of your passengers and the efficiency of your ship. At the same time, they contribute to lowering the maintenance and overall costs and reducing down times as much as possible. Our products warrant the safe conveyance of pressure and drainage lines and other process fluids on board – without altering their quality in the least.

Ships are not only floating cities, but are also essential for the world’s economy. Using the oceans as traffic and commercial routes, applications aboard have to deal with extreme conditions. With regard to longevity and efficiency, preventing corrosion and installing lightweight solutions is more important here than anywhere else. Increasing ship sizes and construction heights are raising the demand for lightly constructed yet perfectly safe systems in the ship. In addition, increasing environmental requirements are directing attention towards emission control and ballast water treatment. At the same time, the focus is always on the desire for passengers for security and comfort.

With GF Piping Systems, corrosion is no longer an issue: The plastic piping systems by GF Piping Systems are noncorrosive and do not have to be replaced throughout the entire service life of the system. Therefore they contribute to the increased reliability of the piping system, while lowering maintenance costs. They are excellently suited for applications involving drinking and sewage water, coolants, acids, leaches and other chemicals, as well as abrasive compounds.

Weighing up to 60 percent less than metal systems, they have lower static requirements and are easier to transport. Innovative jointing technologies such as rapid cementing or integrated electrofusion allow them to be installed up to 50 percent faster.

The energy effi ciency and recyclability are important elements in lowering their environmental impact. To prove the quality, safety and reliability of our products, all relevant certifi cates and approvals are available for our systems worldwide, including those from LR, DNVGL, ABS, RINA, and BV. Compared to competitive materials, plastic solutions cause less CO2 emissions and show a lower ecological footprint, lately forming the basis for sustainable performance.

No maintenance and lower costs with plastic systems on board

GF Piping Systems has been the partner of the global marine industry for more than 20 years and supplies non-corrosive and light plastic piping systems for water treatment and distribution, grey and black water disposal and cooling. They reduce the tare weight and risks to hygiene while increasing the safety of your passengers and crew as well as the efficiency on board.

Non-corrosive system solutions

Our plastic systems cover all fluid applications on board and remain non-corrosive

for the entire service life of the ship (at least 25 years). You dont have to worry about

leaks and serious accidents due to corrosion damage anymore and can concentrate

on your daily business.

More efficiency on board

Plastic systems are up to 60 percent lighter than metallic solutions. This weight

reduction makes it possible to reduce fuel consumption and increase load capacity.

New areas and sales opportunities become accessible. Better, durable insulation

helps increase the efficiency by reducing cooling and heating losses.

Safety and hygiene

Our drinking water solutions reduce the risk of bacterial pathogens in the cabins,

while the cooling solutions increase passenger comfort and preserve food items in

the warehouses, kitchens, and restaurants on board. They protect the health of your

passengers and reputation of the company.

Persistently efficient

Our systems remain free of rust, incrustations and deposits throughout the entire

service life of the ship. They resist chemical stresses, such as chlorine disinfection of

the drinking water system, easily and permanently.

Approvals

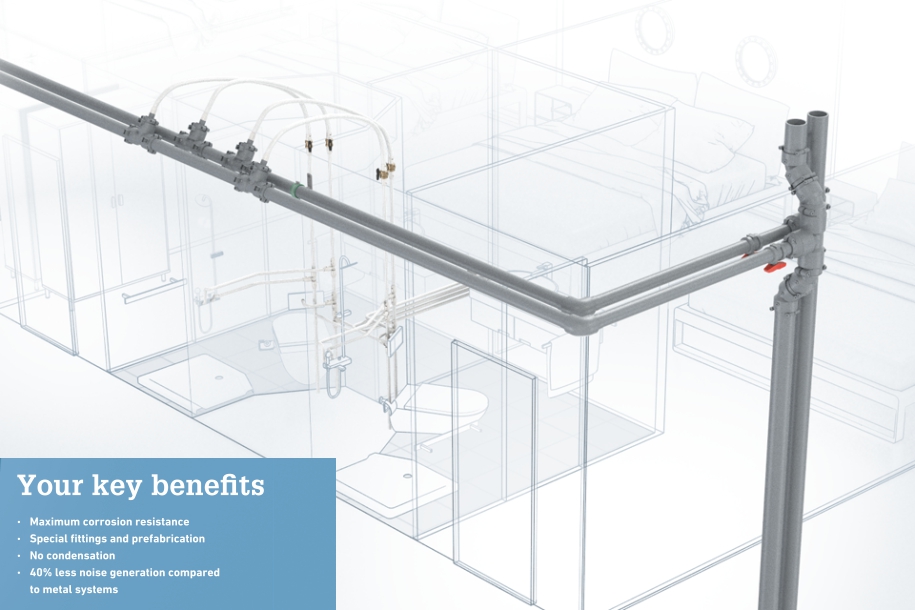

Hot and cold water, fresh water

Effective water supply thanks to simple installation technology. Our systems are ideally suited for drinking water distribution on all types of ships. Cabins, kitchens, restaurants and bars are optimally supplied with fresh water. The high flexibility of the material and the easy installation technology cut time and costs to a minimum. The installers have the option to install individual or continuous lines, ring mains, T-piece branches and continuous lines with circulation possible at every deck and in the risers of the vessel.

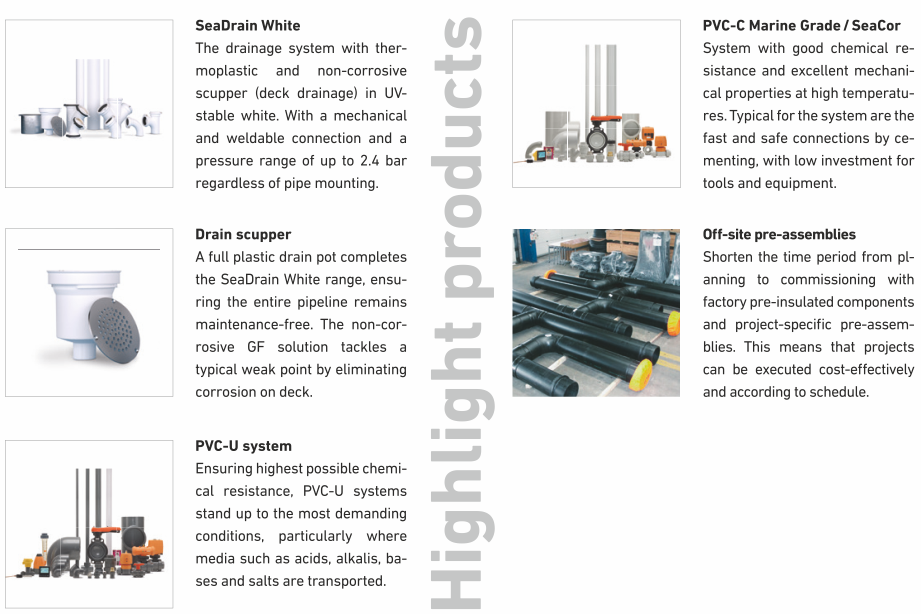

Sewage, black and grey water

Wastewater from sinks and showers as well as from toilets and medical facilities creates grey and black water that has to be conveyed safely to the wastewater treatment system on board. With the solutions from GF Piping Systems a safe transport is guaranteed. Our modern electrofusion, adhesive or mechanical jointing technology is conducive to fast installation and the highly diversifi ed product mix provides installers with the flexibility they require. All our plastic systems do not corrode and provide a long service life.

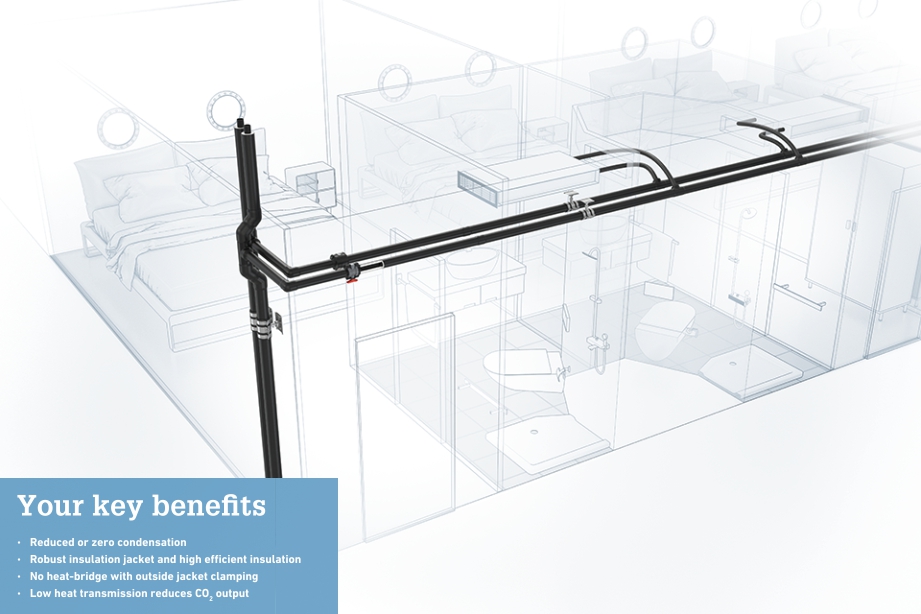

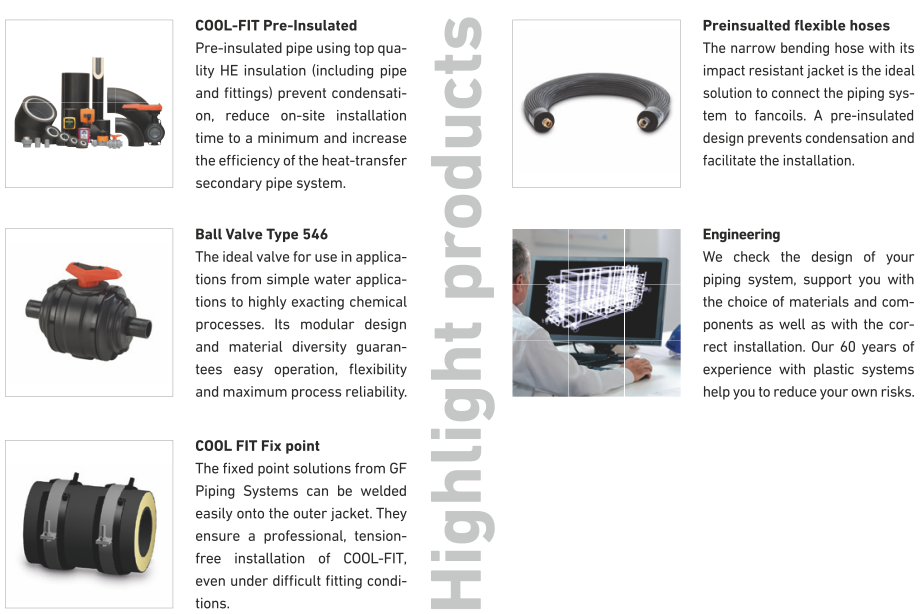

Air conditioning

Air conditioning plays an important role for onboard accommodation as it helps to have a healthy and pleasant atmosphere with respect to temperature and humidity. Thermal comfort can be provided with a direct expansion system for small capacities, for big ships chilled water systems are commonly used.

Thanks to the robust external jacket and the highly efficient insulation the system by GF Piping Systems is the right solution for a long service life on board.

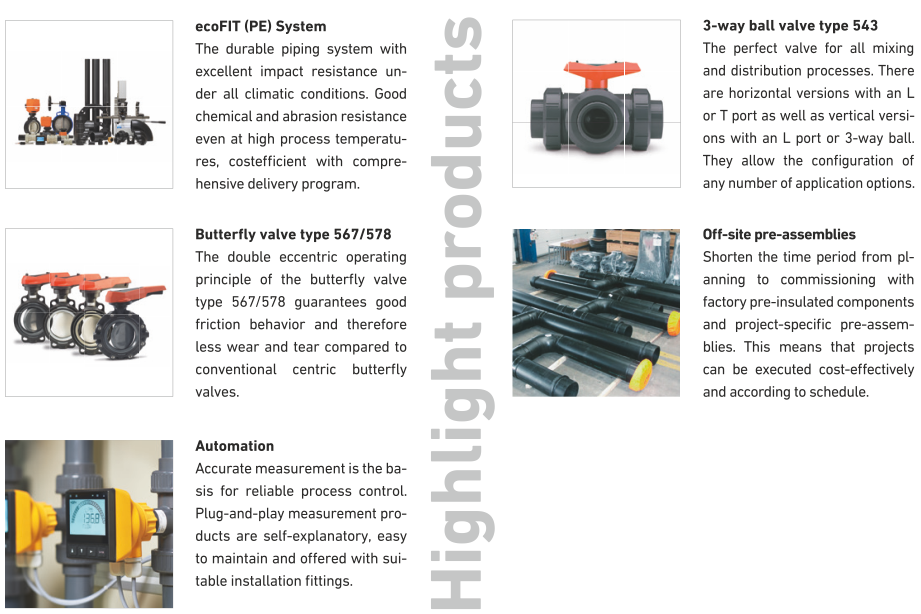

Exhaust gas scrubber

The International Maritime Organization has stipulated a reduction in the maximum sulfur limit in marine fuels from 3.5% to 0.5%. All ships across the globe will mandatorily have to use low-sulfur fuels or gas instead of the high-sulfur fuel oil that currently dominates the market. Ship-owners will have to choose whether they want to use low level sulfur fuel or scrubbing technology or other alternatives in order to comply with stringent requirement.

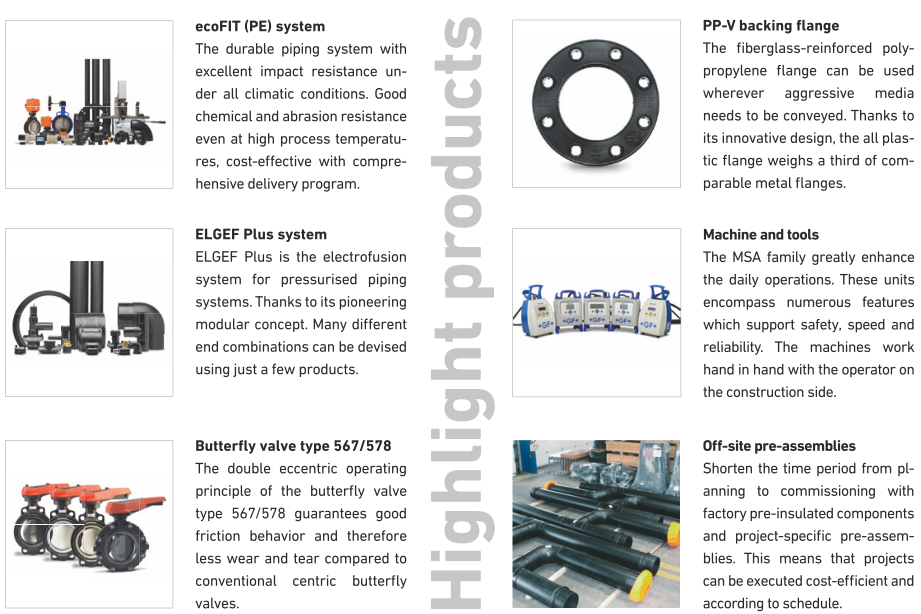

Ballast water treatment

Stabilizing systems with ballast water tanks are essential for safe and effi cient shipping operations. However due to the multitude of marine organisms, ballast water treatment on ships is required to prevent serious ecological risks. With its wealth of experience in water treatment, media filtration, dosing and chemical conveyance, GF Piping Systems off ers various innovative solutions for ballast water treatment unit on ships.

Local experts and help around the clock

Our experienced specialists are located in 34 countries and are therefore always close at hand.

You can obtain information and assistance on our website at any time of day or night.

Help in all project phases

The GF Piping Systems website is a work platform that offers practical assistance for optimum planning, installation, and operation of your system. We provide individual support and application-oriented services along the entire lifecycle of your installation. You can rely on local expert teams, individually tailored training courses as well as on practical online, planning and installation tools. Equipped with the right know-how you can reduce the risk of faulty design and construction work.

Local contacts

GF Piping Systems is represented in 34 countries with its own sales and production companies and experienced experts. This means that you always have local contact partners that can support you throughout all phases of your project. Our experts know the local requirements and specific features and can recommend you solutions that can be used safely and reliably for the project site. This also applies to projects spanning several countries and continents.

English

English Deutsch

Deutsch